The

post mill at Windmill hill, sporting its patent sails. Sadly, all

historic buildings suffer from green growth over the years. Meaning that

they don't look all shiny and white for very long after a fresh coat of

paint. But, you should have seen the rusty hulk this was in the 1980s.

Windmill Hill Mill is a grade II* listed post mill at Herstmonceux in

East Sussex, England which has been restored and now operates as a working mill. The mill is open to the public on most Sundays from Easter until October.

Windmill Hill post mill is run by the Windmill Hill Trust.

Windmill Hill Mill is a post mill on a two-storey roundhouse. She has four patent sails carried on a cast-iron windshaft and was winded by a tailpole. Winding is now

computer-controlled, with an automatic turning device installed that receives information about the wind direction from sensors mounted on the mill. The wooden brake-wheel is of clasp-arm construction, with oak arms and an elm rim. It has 104 cogs and drives a stone nut with twelve cogs. The tail wheel is of cast iron, with 130 cogs. The mill drove two pairs of millstones, arranged head and tail. The headstones are Peak stones and the tailstones are French Burrs.

The body of the mill is 21 feet 3 inches (6.48 m) long and 12 feet 3 inches (3.73 m) wide, the largest surviving post mill by floor plan in the United Kingdom. It is 50 feet 10 inches (15.49 m) high to the roof, the second tallest post mill in England. The roundhouse is 22 feet 6 inches (6.86 m) in diameter and has a single-storey lean-to extension of part of its circumference. When originally built, the mill had a single-storey roundhouse which was raised in the 1850s. The Hammond's Sweep Governor was fitted in the 1870s.

HISTORY

Windmill Hill Mill was built c. 1814 by William Medhurst, the Lewes millwright. It was working by wind until 1893, when it was stopped owing to a weak weatherbeam. It is the largest post mill in

Sussex, and is unique in that it is fitted with Hammond's Patent Sweep Governor, a feature previously fitted to Jack Mill, Clayton.

After work by wind had ceased, milling was continued by means of a steam-powered mill set up in the roundhouse.

Further

down the road in Lime

Park, Charles

de Roemer had started to generate electricity

for the village of Herstmonceux. Times were changing, with internal

combustion engines taking over from steam, even for giant oil

tankers and cargo ships.

Neve, the Warbleton millwright was responsible for the fitting-out of the roundhouse as a power mill.

It

would be around ninety years before wind

power once again became commercially viable to generate electricity

in on and offshore wind farms. Now the cheapest form of electricity

generation. But we are still reliant on fossil

fuels and nuclear

power, because of lackluster leadership with one hand in the pockets

of the coal

and uranium thugs who are killing our planet. Nuclear weapons are now

illegal under United Nation (international) law. We think nuclear

reactors should also be illegal.

The mill stood derelict for

over a century with major structural faults, including both side girts being broken.

During its life the mill was raised in order to catch the wind better. It is thought that the present two storey roundhouse was also built at this time. The roundhouse served both as protection for the

timber trestle against the weather and also as a storage area for grain and flour. The roundhouse also has a 'second skin' around part of the mill which acts as extra storage.

The mill has weathered several severe

storms, including the hurricane of 1987 during which another Sussex post mill was blown over and destroyed.

RESTORATION

In 1994, a supporting steel framework was placed around the mill, and the remaining iron sheeting that clad the breast and sides of the mill removed. The tail of the mill was clad in

plywood to keep the weather out. A trust was set up in 1995, aiming to prevent further deterioration in the condition of the mill, and to assess options for restoration. The Heritage Lottery Fund agreed in principle to support the restoration work. English Heritage funded the study to produce an application for lottery funds to restore the mill.

A detailed study of the mill was made in the summer of 2000. IJP Millwrights of Binfield Heath were contracted to restore the mill. A grant of £570,000 towards a total restoration cost of £770,000 was made in December 2001, this being the biggest single Lottery grant to an individual windmill. The mill was dismantled during November and December 2003, and taken in sections to IJP's

workshops in Oxfordshire. Modern millwrighting techniques, including CAD were used in the assessment of the structure of the mill in preparation for the rebuild. It was found that one of the quarterbars in the trestle would need to be replaced due to damage done by Death Watch Beetles.

The rebuilt frame of the mill was lifted back onto the main post on 7 September 2004. The sails were fitted to the mill between 24 November and 3 December 2005.

The restoration took two and a half years to complete.

On 19 November 2014 the Heritage Lottery Fund announced the grant of £80,800 for restoration of machinery and sweeps to grind flour. On 5 November 2015, the full patent sweeps turned again for the first time in 120 years.

MILLERS

Beeney 1845 - 1877

Charles Edwin Hammond 1878 - 1887

Henry Harmer 1887 - 1913

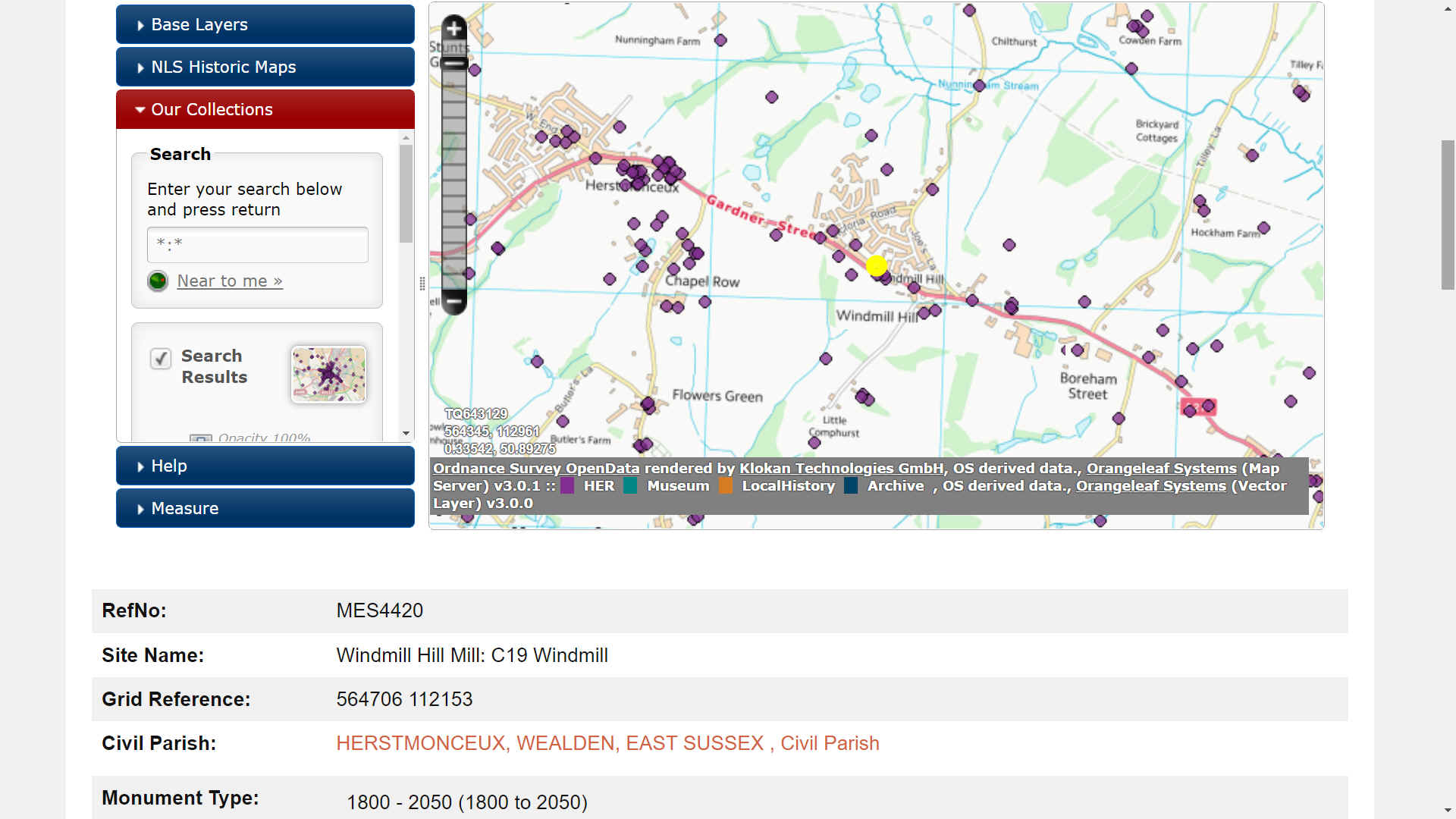

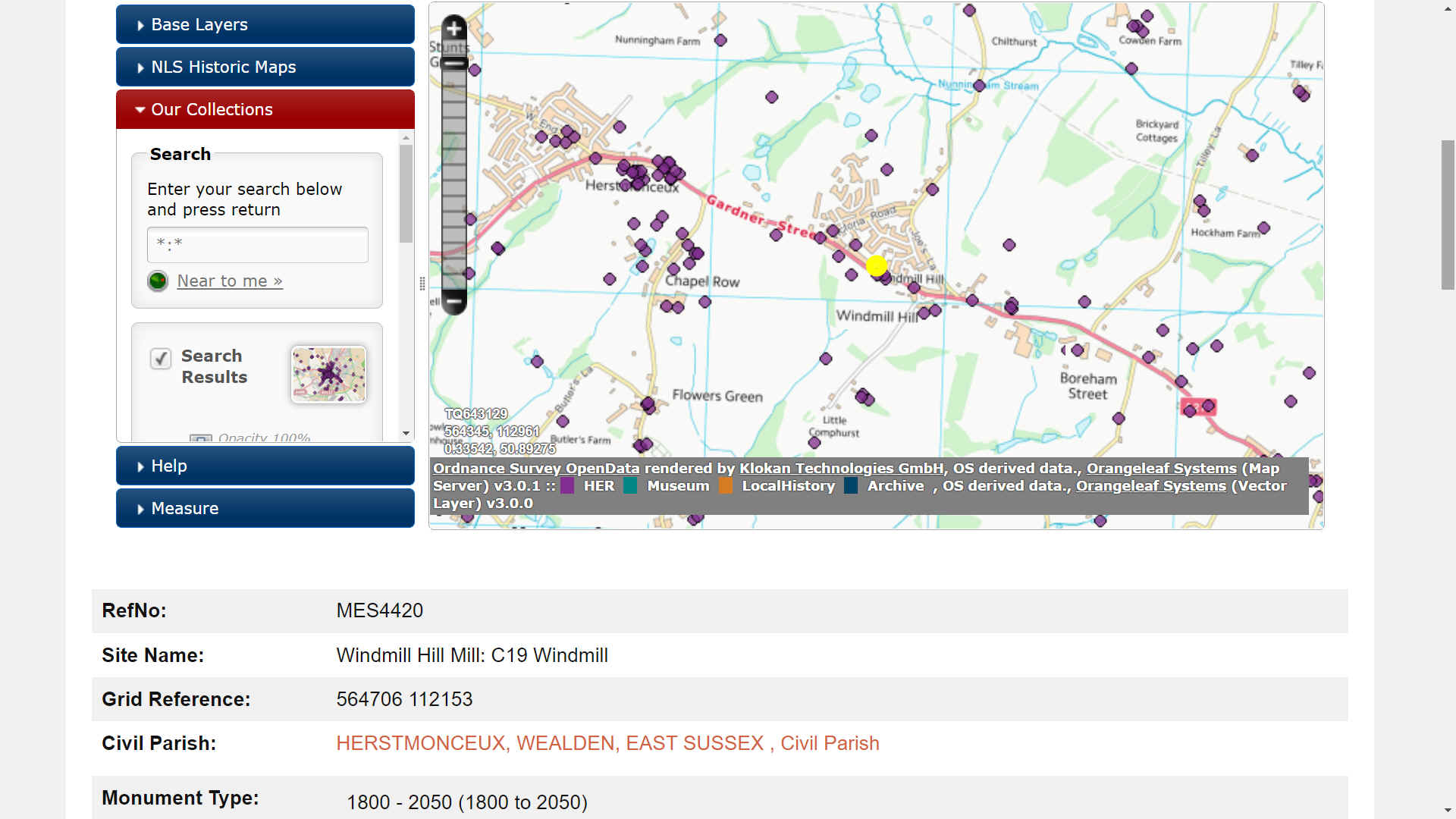

THEKEEP - WINDMILL HILL MILL: C19

RefNo: MES4420

Site Name: Windmill Hill Mill: C19 Windmill

Grid Reference: 564706 112153Civil

Parish: HERSTMONCEUX, WEALDEN, EAST SUSSEX , Civil Parish

Monument Type: 1800 - 2050 (1800 to 2050)1800 - 2050 (1800 to 2050)

Summary: 19th century Post mill built c.1814, restored, working.

DESCRIPTION:

Post type windmill. Built c1814 by the Lewes mill-wright, Medhurst. It is the largest postmill in the country as regards body size, with a basic floor area of 21' 3"x 12' 3" plus 1' 6" projection on the windward face, at 48ft the tallest windmill in Sussex and the last remaining mill in England to possess the remains of a centrifugal governor system for controlling the sail area, though at the time of inspection this had been removed for safekeeping elsewhere. It comprises a 2 storey tarred Flemish bond brickwork roundhouse with sash windows and a 3 storey timber-framed body with ogee head clad in weatherbording and further clad in sheet iron on the weather sides.

Most of the ladder and part of the tailpiece survives but the sails are missing. The roundhouse contains on the ground floor the bases of 4 brick piers supporting the main post and trestle on the first floor and a heavily joisted ceiling. The first floor has the crosstrees, quarterbars and main post carved with the date 1856 and bins for steam driven stones built on the quarterbars. The body bottom floor has the upper part of the main post supporting the crowntreee, an oscillating sieve grader and the bottom of the wire cylinder flour dresser, a wire cylinder grain cleaner and extractor fan, the complete tentering gear and governor to tail millstones, part of the tentering gear to the head stones, part of the meal bins and the horse to the millstone tun. The body first floor has the cast iron windshaft carrying the brake wheel and tailwheel, the tail millstones (bedstones in place, runner stone resting on crowntree), driving quants and bevel pinions to both sets of stones, wire cylinder flour dressing machine and driving gears fairly complete and transverse shaft with pinion and pulley for driving the flour dresser from the brake wheel.

The body second floor contains the top of the brake wheel with pinion and pulley to drive the sack hoist, the sack hoist bollard and pulley, various bins to feed the millstones and flour dresser and part of the centrifugal governor system for sail regulation. This mill never had a tailpole but was turned to the wind by pushing the body round manually using the tailpole. It ceased turning in 1893 when steam-driven stones were set up in the

roundhouse.

Post mill erected on this site between 1814 and 1819. Milling stopped in 1893 because of the unsafe nature of the weatherbeam and the rest of the main structure of the three-floored body.

Dendro anayalsis undertaken in 2005 showed the mill dates to c.1812-14.

Post mill, Grade II* Listed. It was built c.1814 and is the largest post mill in the country and the tallest in Sussex. It had a two-storey roundhouse and drove one pair of French Burr stones and one pair of Derbyshire Peak stones and worked as a corn mill. In 1876 a unique mechanical refinement in the form of the patent Hammond Sweep Governor was installed to provide a constant speed windmill. It worked by wind until 1893 and subsequently by steam.

By the First World War it had ceased to work and had become derelict. Structural support was constructed in 1993 and a charitable trust formed to oversee the restoration which was completed by 2006. It is now a working mill open to the

public. In 2003 it was reported that a grant of £90,000.00 had been awarded, by English Heritage towards the restoration of the windmill, along with 350,000.00 from Esme Fairbairn Foundation . This provided match funding from the HLF for £577,000.00 to restore the mill (as

above).

A

nice picture of the mill from the rear, showing the access staircase and

roundhouse, with worn out grinding wheels.

LINKS

& REFERENCE

https://www.thekeep.info/collections/getrecord/ESHER_MES4420

https://www.thekeep.info/collections/getrecord/ESHER_MES4420

https://www.thekeep.info/collections/getrecord/ESHER_MES17044

https://www.thekeep.info/collections/getrecord/ESHER_MES17044

https://windmillhillwindmill.org/

https://www.eastsussex.gov.uk/environment/archaeology/her

https://www.thekeep.info/east-sussex-historic-environment-record-her/